Waste water conductivity is a critical parameter in the

field of water quality assessment and management.

The conductivity of waste

water is a measure of its ability to conduct electrical current, which is

influenced by the presence of various dissolved ions and contaminants.

Understanding waste water conductivity is essential for evaluating the overall quality of water, identifying potential sources of pollution, and determining the effectiveness of treatment processes.

1. Definition of Conductivity

Let’s start with the basics – conductivity. In simple terms, conductivity refers to the ability of a substance to conduct electricity. When it comes to waste water, conductivity is a measure of how well it can transmit an electric current. The higher the conductivity, the more easily electricity can flow through the water.

But why should we care about conductivity in waste water? Well, conductivity can provide valuable insights into the quality and composition of the water. By measuring conductivity, we can determine the level of dissolved ions, salts, and other substances in the water. This information is crucial for assessing the health and safety of the environment and for managing waste water treatment processes effectively.

2. Factors Affecting Conductivity in Waste Water

2.1 Dissolved Solids and Salinity

One of the major factors influencing conductivity in waste water is the presence of dissolved solids. These solids can include various substances like salts, minerals, and organic compounds. The more dissolved solids there are in the water, the higher the conductivity. So, if you find yourself swimming in the Dead Sea, don’t be surprised if you feel a slight electric buzz!

2.2 Temperature and pH

Temperature and pH also play a role in the conductivity of waste water. As temperature increases, so does the conductivity. Similarly, pH levels can affect conductivity.

Generally, higher pH values tend to result in higher conductivity.

2.3 Presence of Chemicals and Contaminants

Chemicals and contaminants present in the waste water can significantly impact conductivity. For example, certain chemicals can increase conductivity by contributing ions that enhance electrical conductivity. On the other hand, some contaminants can actually decrease conductivity by interfering with the flow of electricity.

3. Measurement Techniques for Waste Water Conductivity

3.1 Electrical Conductivity Sensors

There are several methods to measure conductivity in waste water, and one popular approach is using electrical conductivity sensors. These sensors work by applying an electric current to the water and measuring its response. They provide real-time data and are often used in industrial and research settings to monitor conductivity levels.

HI98195

Multiparameter pH/ORP/EC/Pressure/Temperature Waterproof Meter

The HI98195 is a waterproof portable logging multiparameter meter that monitors up to 10 different water quality parameters including 5 measured and 5 calculated.

The microprocessor based multi-sensor probe allows for the measurement of key parameters including pH, ORP, conductivity, and temperature. The probe transmits readings digitally to the meter, where data points can be displayed and logged. The complete system is simple to setup and easy to use.

The HI98195 is supplied with all necessary accessories and packaged in a durable carrying case.

- Multi-Parameter Display

- Multi-sensor Probe

- USB Connection

Waterproof Protection

The meter is enclosed in an IP67 rated waterproof casing and can withstand immersion in water at a depth of 1 m for up to 30 minutes. The probe features an IP68 rating for continuous immersion in water.

Waterproof Protection

The meter is enclosed in an IP67 rated waterproof casing and can withstand immersion in water at a depth of 1 m for up to 30 minutes. The probe features an IP68 rating for continuous immersion in water.

3.2 Laboratory Analysis Methods

For more precise and comprehensive analysis, laboratory methods come into play. These involve collecting samples of waste water and conducting tests using sophisticated equipment. Laboratory analysis methods can provide detailed information about the composition and conductive properties of the water.

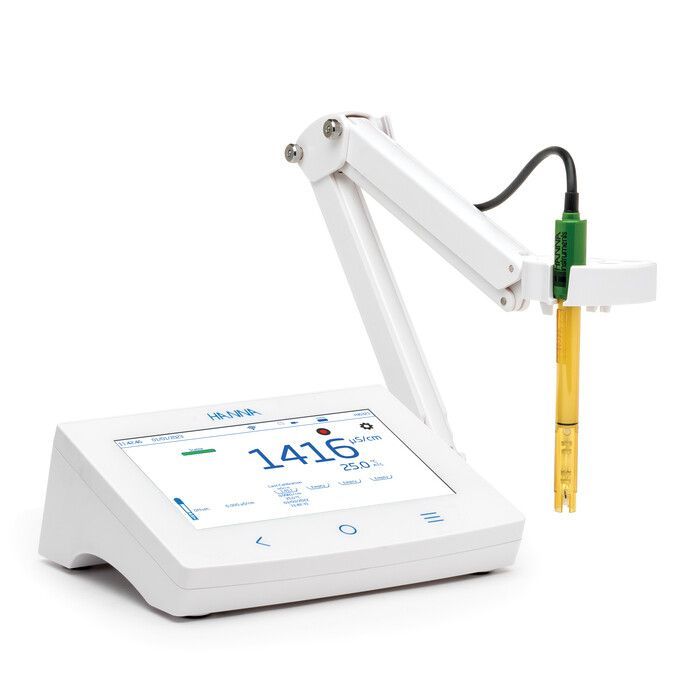

HI6321

Advanced Conductivity Benchtop Meter

HI6321 is a streamlined Conductivity/Resistivity/TDS/Salinity/Temperature benchtop meter with a large touch screen display, comprised of a housing and an integrated conductivity measurement module.

- 7-inch capacitive touch screen with multi-touch support

- Capacitive touch back, home and system menu keys

- User-friendly icons and symbols allow users to easily navigate and interpret the instrument functions

Measure μS/cm, mS/cm (Conductivity); Ω·cm, kΩ·cm, MΩ·cm (Resistivity); ppm, ppt (TDS); ppt, PSU, % (Salinity) with temperature

Measure μS/cm, mS/cm (Conductivity); Ω·cm, kΩ·cm, MΩ·cm (Resistivity); ppm, ppt (TDS); ppt, PSU, % (Salinity) with temperature

HI6321

Advanced Conductivity Benchtop Meter

Maximize Your Testing Potential

3.3 Online Monitoring Systems

To keep a constant eye on waste water conductivity, online monitoring systems are becoming increasingly popular. These systems utilize sensors and data loggers to continuously monitor conductivity levels in real-time. They can alert operators if conductivity exceeds certain thresholds, enabling quick response and action.

When choosing a controller, it is important to consider factors such as accuracy, reliability, maintenance requirements and cost.

The type of controller chosen will depend on the specific needs of the facility and the degree of control required over the water quality parameters.

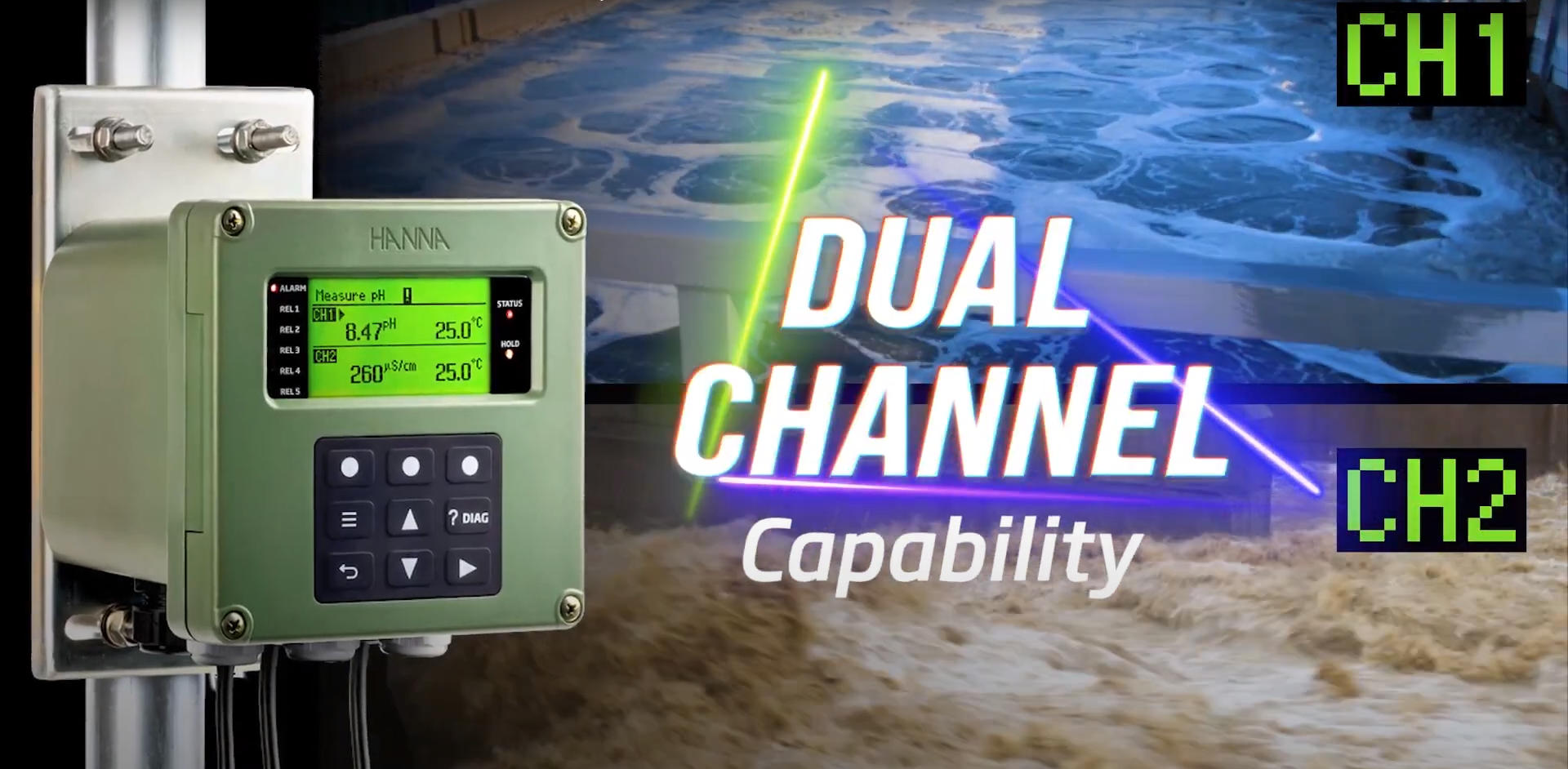

HI510 • HI520

Single and Dual-Channel Universal Process Controllers

HI510 and HI520 are advanced process controllers that can be configured for applications requiring monitoring and/or control of four main water-analysis parameters: pH, ORP, Conductivity and Dissolved Oxygen.

These controllers feature a digital probe input(s) that automatically detects and updates the controller with the parameter that it measures.

HI520 is Hanna’s first dual-input process controller that accepts virtually any combination of compatible probes. Designed to adapt to unique process control requirements, users have the option to enable or disable each channel independently.

Additionally, HI520 introduces enhanced industrial control by operating a control-loop system whereby users have the option to run channel control either independently or configure to be triggered sequentially upon reaching the other channel’s set point(s) (1, 2, or both).

The device operates a logical channel with built-in mathematical functions. This function is intended for when the controller works as an analyzer for monitoring high/low parameter levels between two identical inputs with identical measuring configurations.

These Universal Process Controllers offer wall, pipe and panel mounting options and feature a large backlit dot matrix display for easy viewing and provide an intuitive interface for setup options.

offer wall

pipe

panel

The controllers utilize multi-color LEDs for easy viewing of the instrument’s status including relay activation, in alarm mode, or in hold status. All programming operations are done through the low profile vulcanized rubber keypad or with an RS485 connection to a Modbus-compliant supervisory computer.

⇒ Waterproof IP65 (NEMA 4X) enclosure

⇒ Large backlit LCD

⇒ Multi-color LED status indicators

⇒ Audible alarm

⇒ Tactile rubberized keypad

⇒ Universal mounting

⇒ Universal Hanna digital probe pH, ORP, EC, DO, opDO

Boost Your Water Testing Efficiency With Our NEW HI520 Dual-Channel Universal Process Controller

Digital Inputs

- Two digital inputs for remotely triggering, cleaning and hold functions

Analog Outputs

- Up to 4 analog outputs and 5 relays used for control and for sending a signal to data loggers, PLC, SCADA and other remote monitoring systems

- 0-20 mA or 4-20 mA

- Scalable in selecting values for the range

- Can be used for control of pumps and valves

- On alarm state can output a 22 mA signal to the monitoring system

Digital Communication

- The Modbus-compliant unit can be integrated within a Modbus-based network and connected to other industrial electronic devices.

The following tasks may be accomplished remotely:- Monitoring, using the virtual LCD (limited to a single remote control in the entire network)

- Setup

- Loading the Setup configuration file to a controller

- RS485 Digital output for PC and other device connectivity

Relays

- Up to 5 control and 1 alarm electromechanical relays

- Replaceable 5A fuses to protect all relays

- Extractable terminal blocks for easy wiring

- Relay options include single pole double throw (SPDT) and single pole single throw (SPST)

- Control relays can be programmed for:

- On/Off,

- Proportional,

- PID control

- Cleaning

- Hold functions

- Configurable alarm relay

- Relays terminal blocks and their wires paths are separated from the low voltage section for additional safety

Industrial Smart Probes Compatible with the HI510 - HI520 Universal Process Controller

Conductivity and Temperature

Recommended for clean, noncorrosive water applications, the HI7630-28 series can be calibrated using a standard with a value close to the measurement value.

The HI7630-48 series provides an exceptionally stable measurement over a wide measure range and does not require frequent calibration.

Probes can be installed directly in-line, immersed in a tank, or flow cell. The conductivity probes are suited for continuous measurement of conductivity and associated parameters required in applications such as water treatment, drinking water, feedwater condensate or other clean water applications.

4. Implications of High Conductivity In Waste Water

4.1 Effect on Aquatic Life

When waste water has high conductivity levels, it can have negative effects on aquatic life. Elevated conductivity can disrupt the balance of ions in the water, making it difficult for aquatic organisms to regulate their internal processes. This can lead to stress, poor reproduction, and even death for sensitive species.

4.2 Corrosion and Scaling in Infrastructure

High conductivity in waste water can also wreak havoc on infrastructure. It can accelerate the corrosion of pipes and other metal components, leading to costly repairs and replacements. Additionally, the deposition of scale caused by elevated conductivity can clog pipes and reduce flow efficiency.

4.3 Impact on Water Treatment Processes

Water treatment processes can be negatively impacted by high conductivity in waste water. Excessive conductivity can interfere with the effectiveness of disinfection methods, such as chlorination. It can also hinder the removal of contaminants and impurities, making the treatment process less efficient. So, let’s keep our waste water conductivity in the optimal zone – not too high, not too low, but just right!

So, next time you come across conductivity in waste water, remember that it’s not just about electricity flowing through pipes. It’s about understanding the composition of the water, protecting the environment, and ensuring efficient waste water management.

5. Strategies for Controlling and Managing Waste Water Conductivity

5.1 Source Control and Pollution Prevention

When it comes to waste water conductivity, prevention is key. Implementing source control measures and pollution prevention strategies can significantly reduce the conductivity of waste water before it even enters the treatment system. This can involve practices such as minimizing the use of chemicals, properly managing and disposing of hazardous materials, and implementing good housekeeping practices to prevent the accumulation of contaminants.

5.2 Advanced Treatment Technologies

Advanced treatment technologies play a crucial role in managing waste water conductivity. Technologies such as reverse osmosis, electrocoagulation, and ion exchange can effectively remove dissolved ions and contaminants, resulting in a significant reduction in conductivity. These technologies are often employed as part of a comprehensive treatment system to ensure that waste water meets the required quality standards before being discharged.

5.3 Use of Chemical Additives and Conditioners

Chemical additives and conditioners can also be utilized to manage waste water conductivity. These additives can help to neutralize or precipitate dissolved ions, reducing the overall conductivity of the water. Additionally, conditioners can enhance the performance of treatment processes by improving flocculation or settling of solids.

However, it’s important to carefully evaluate the potential environmental impact of these additives before incorporating them into waste water treatment systems.

Have questions?

Contact a Hanna Technical Specialist at [email protected] or using our contact form.

AUTHOR:

Nives Vinceković Budor, mag.ing.chem.ing.

With Great Products

Come Great Results