Water effluent monitoring is a critical process that helps protect our water sources and aquatic life.

Monitoring the pH, EC, DO levels, in wastewater and surface water, is essential to ensure that the water is free from harmful contaminants and safe for human use.

The use of pH/EC/ORP/DO controllers has revolutionized the way we monitor water quality by providing accurate and reliable measurements in real-time.

1. Introduction to Water Effluent Monitoring

Water effluent monitoring is the process of regularly testing the quality of wastewater being discharged from a facility to ensure that it meets regulatory standards and does not harm the environment. This monitoring is essential to prevent contamination of water sources and to protect aquatic life.

One of the key components of water effluent monitoring is pH, electrical conductivity (EC) and dissolved oxygen (DO) measurements.

The most important parameters in wastewater monitoring include pH, EC, D.O., biochemical oxygen demand (BOD), chemical oxygen demand (COD) and turbidity.

These parameters are essential to ensure the quality of water leaving treatment plants, as discharge into surface waters can have significant impacts on public health and environmental sustainability.

pH levels indicate the acidity or alkalinity of the water and can affect the effectiveness of treatment processes.

pH neutralization of waste water effluents:

Automatization with HI510 Universal process controller

BOD (biochemical oxygen demand) measures the amount of organic matter in wastewater that can be decomposed by microorganisms, which is crucial for understanding how much oxygen is needed for treatment processes.

COD (chemical oxygen demand) measures both biodegradable and non-biodegradable organic matter, providing insight into the efficacy of specific treatment methods.

Rapid Method for COD Determination in Industrial Waste Water

2. Understanding the Importance of pH, ORP, EC and DO

What is pH and why is it important?

pH is a measure of the acidity or basicity of a solution, ranging from 0 to 14.

In water effluent monitoring, pH is important because it affects the solubility of pollutants and the biological activity of microorganisms.

The ideal pH range for water effluent discharge is between 6 and 9.

A pH imbalance can have serious consequences on the environment and human health.

An acidic pH can cause corrosion to pipes, pumps and other equipment. It can also harm aquatic life and vegetation. A high pH can cause scaling and buildup on surfaces, which can reduce efficiency and damage equipment.

Understanding EC and its significance in water effluent monitoring

EC measures the ability of water to conduct electricity, which is directly related to the concentration of dissolved ions such as salts and minerals (TDS).

High levels of dissolved solids can be harmful to aquatic life and can cause scaling in pipes and equipment.

The role of dissolved oxygen (DO) in water quality

DO is a measure of the amount of oxygen dissolved in water, which is essential for aquatic organisms to survive. Low levels of DO can indicate the presence of pollutants or organic matter that consume oxygen.

DO monitoring is critical to maintain healthy aquatic ecosystems and prevent fish kills.

Why ORP is a measure of water quality?

Oxidation-Reduction Potential (ORP) is an important measure of water quality, particularly in effluent water. ORP represents the capacity of a solution to accept or donate electrons, which can be used as an indication of the presence and concentration of different chemicals in the water. In wastewater treatment plants, ORP measurements are commonly used to monitor disinfection processes, such as when chlorine is added to effluent water. High ORP values indicate that there is enough chlorine present to effectively kill harmful microbes and pathogens in the water.

However, too high ORP levels can also cause damage to equipment and lead to increased costs due to excessive use of chlorine.

Regular measurement and management of ORP levels are therefore necessary for effective treatment of effluent water, ensuring safe discharge into the environment and protecting public health.

3. The Role of Controllers in Water Effluent Monitoring

What is a process controller?

A process controller is a device that continuously monitors the pH, ORP, EC, and/or DO levels in water and adjusts the chemical dosing or aeration systems accordingly to maintain optimal water quality. These controllers are used in water treatment plants, industrial facilities and other locations where water effluent must be closely monitored to meet environmental regulations.

The benefits of using controllers in water effluent monitoring

Using process controllers in water effluent monitoring provides several benefits, including improved efficiency, increased accuracy, and reduced chemical and energy consumption. These controllers also allow for real-time adjustments to water quality parameters, resulting in better control over the effluent quality and preventing excess discharge of pollutants.

4. Different Types of Water Controllers and Their Features

On/off controllers

On/off controllers are the most basic type of controller, which turn on a pump or valve to add or remove chemicals when the water quality falls outside of the desired range. These controllers are cheaper than other types, but they can be less accurate and may result in over or underdosing.

Proportional controllers

Proportional controllers adjust the dosing rate based on the deviation of the measured parameter from the desired setpoint. These controllers are more accurate than on/off controllers and require less maintenance, resulting in cost savings over time.

PID controllers

PID (Proportional Integral Derivative) controllers use a more complex algorithm to adjust the dosing rate based on past and present measurements of the water quality parameter. These controllers are the most accurate and can provide precise control over water quality, but they also tend to be the most expensive.

When choosing a controller, it is important to consider factors such as accuracy, reliability, maintenance requirements and cost.

The type of controller chosen will depend on the specific needs of the facility and the degree of control required over the water quality parameters.

HI510 • HI520

Single and Dual-Channel Universal Process Controllers

HI510 and HI520 are advanced process controllers that can be configured for applications requiring monitoring and/or control of four main water-analysis parameters: pH, ORP, Conductivity and Dissolved Oxygen.

These controllers feature a digital probe input(s) that automatically detects and updates the controller with the parameter that it measures.

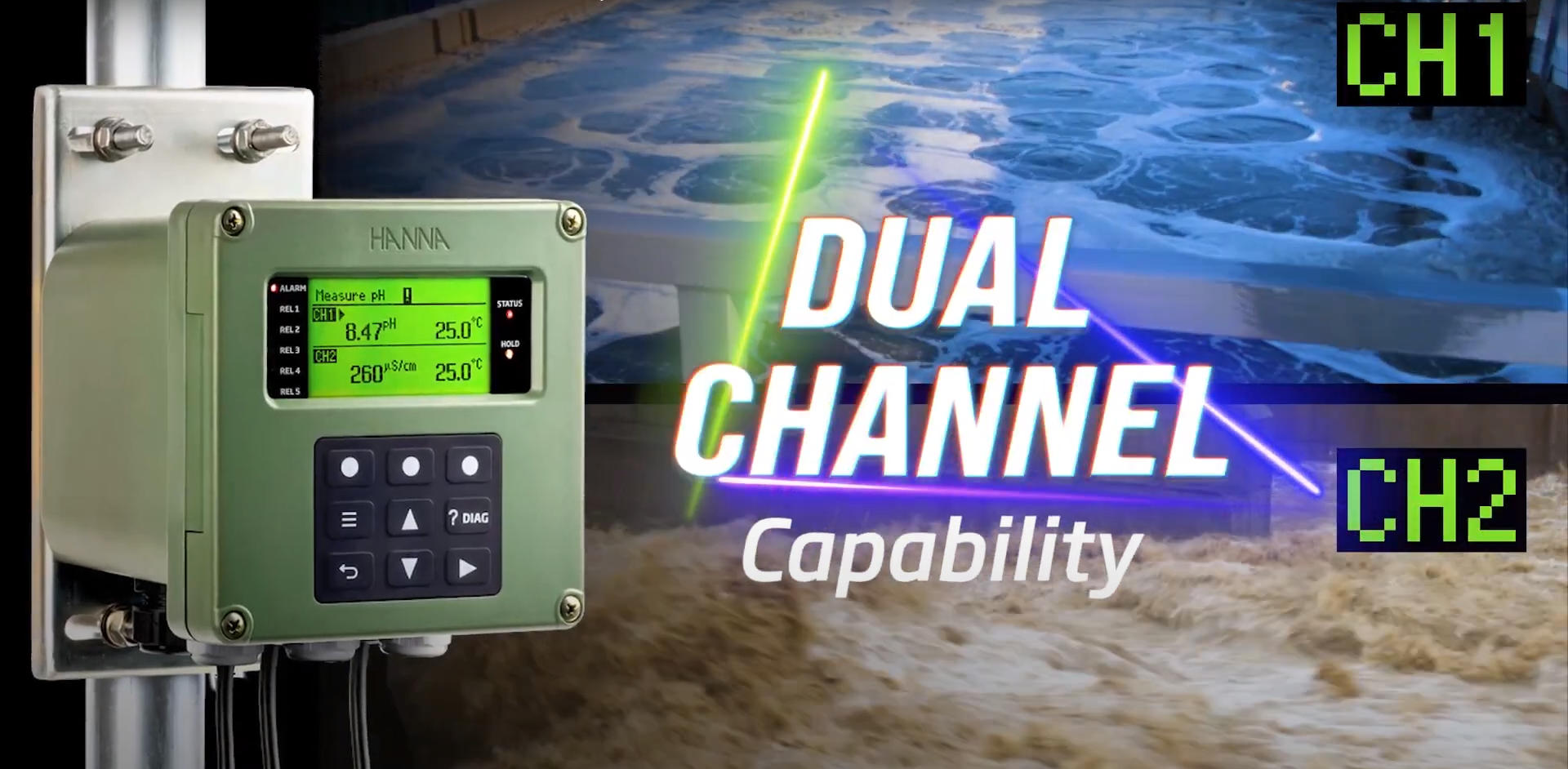

HI520 is Hanna’s first dual-input process controller that accepts virtually any combination of compatible probes. Designed to adapt to unique process control requirements, users have the option to enable or disable each channel independently.

Additionally, HI520 introduces enhanced industrial control by operating a control-loop system whereby users have the option to run channel control either independently or configure to be triggered sequentially upon reaching the other channel’s set point(s) (1, 2, or both).

The device operates a logical channel with built-in mathematical functions. This function is intended for when the controller works as an analyzer for monitoring high/low parameter levels between two identical inputs with identical measuring configurations.

These Universal Process Controllers offer wall, pipe and panel mounting options and feature a large backlit dot matrix display for easy viewing and provide an intuitive interface for setup options.

offer wall

pipe

panel

The controllers utilize multi-color LEDs for easy viewing of the instrument’s status including relay activation, in alarm mode, or in hold status. All programming operations are done through the low profile vulcanized rubber keypad or with an RS485 connection to a Modbus-compliant supervisory computer.

⇒ Waterproof IP65 (NEMA 4X) enclosure

⇒ Large backlit LCD

⇒ Multi-color LED status indicators

⇒ Audible alarm

⇒ Tactile rubberized keypad

⇒ Universal mounting

⇒ Universal Hanna digital probe pH, ORP, EC, DO, opDO

Boost Your Water Testing Efficiency With Our NEW HI520 Dual-Channel Universal Process Controller

Digital Inputs

- Two digital inputs for remotely triggering, cleaning and hold functions

Analog Outputs

- Up to 4 analog outputs and 5 relays used for control and for sending a signal to data loggers, PLC, SCADA and other remote monitoring systems

- 0-20 mA or 4-20 mA

- Scalable in selecting values for the range

- Can be used for control of pumps and valves

- On alarm state can output a 22 mA signal to the monitoring system

Digital Communication

- The Modbus-compliant unit can be integrated within a Modbus-based network and connected to other industrial electronic devices.

The following tasks may be accomplished remotely:- Monitoring, using the virtual LCD (limited to a single remote control in the entire network)

- Setup

- Loading the Setup configuration file to a controller

- RS485 Digital output for PC and other device connectivity

Relays

- Up to 5 control and 1 alarm electromechanical relays

- Replaceable 5A fuses to protect all relays

- Extractable terminal blocks for easy wiring

- Relay options include single pole double throw (SPDT) and single pole single throw (SPST)

- Control relays can be programmed for:

- On/Off,

- Proportional,

- PID control

- Cleaning

- Hold functions

- Configurable alarm relay

- Relays terminal blocks and their wires paths are separated from the low voltage section for additional safety

Industrial Smart Probes Compatible with the HI510 - HI520 Universal Process Controllers

pH and Temperature

ORP and Temperature

These smart industrial ORP probes are used for the measurement of the ratio of oxidized to reduced species in the process.

Together with the Hanna Instruments HI510, they can monitor and control disinfection chemicals or follow and control a critical oxidation or reduction reaction.

HI2004-18 and HI2014-18 platinum sensor series, designed to provide the best response over a wide range of applications

Conductivity and Temperature

Recommended for clean, noncorrosive water applications, the HI7630-28 series can be calibrated using a standard with a value close to the measurement value.

The HI7630-48 series provides an exceptionally stable measurement over a wide measure range and does not require frequent calibration.

Probes can be installed directly in-line, immersed in a tank, or flow cell. The conductivity probes are suited for continuous measurement of conductivity and associated parameters required in applications such as water treatment, drinking water, feedwater condensate or other clean water applications.

Galvanic Dissolved Oxygen

The HI7640-18 series are galvanic-style oxygen probes designed for use with the Hanna Instruments HI510 Universal Process Controller.

The probe is suited for continuous measurement of oxygen dissolved in water.

An integral temperature sensor measures water temperature and adjusts the probe signal over the specified temperature range.

The result is reliable dissolved oxygen (DO) concentration or percent saturated measurements.

Suitable for control applications in municipal and industrial wastewater treatment, the probe can be installed directly in-line, immersed in a tank, or in a flow cell installation.

Optical Dissolved Oxygen

The HI7640-58 series are optical dissolved oxygen probes with HI764113-1 DO Smart Caps for measurements of dissolved oxygen.

When paired with the controller, the system provides accurate DO measurements auto-compensated for barometric pressure, salinity (manually set), and temperature.

Suitable for control applications in municipal and industrial wastewater treatment, where optimizing oxygen transfer is a key element, the probe can be installed directly in-line, immersed in a tank, or in a flow cell installation.

- Factory calibrated Smart Cap

- Low maintenance (no electrolyte refill or membrane replacement)

- Measurement reliability independent of flow rate

- Reduced response time

- Stable readings even when oxygen concentration is low

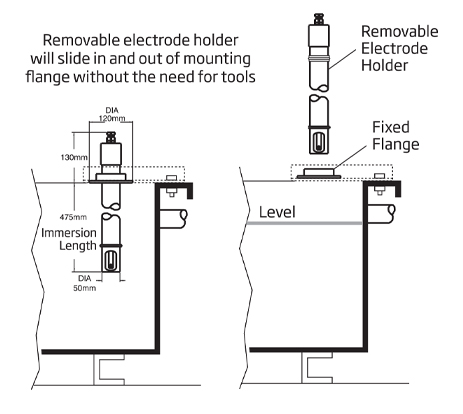

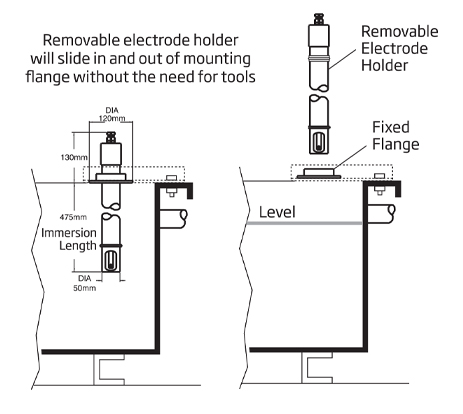

Probes can be installed directly in the tank with specifically designed electrode holders

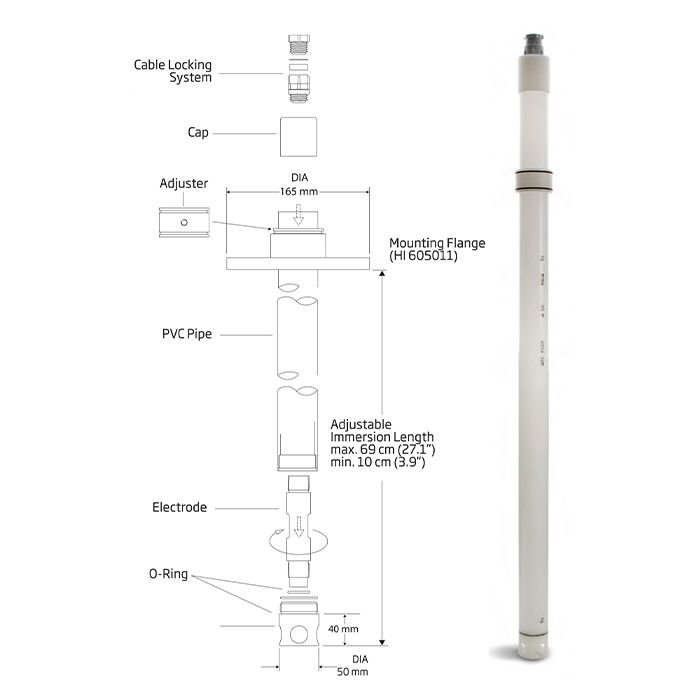

HI60501

Immersion Electrode Holders

The HI60501 is an electrode holder for immersion installation for tanks, vessels, baths and open channels. This electrode is made of rugged PVC, and can withstand most chemicals.

5. Installation and Maintenance of process controllers

pH/EC/ORP/DO controllers are beneficial for water effluent monitoring, but it’s imperative to ensure their proper installation and maintenance to ensure accurate measurements.

Proper installation techniques to ensure accurate measurements

The installation process for pH/EC/ORP/DO controllers should be conducted by a professional and experienced technician. They need to ensure that the sensor probes are placed in adequate positions and secured correctly to avoid any potential damage. Additionally, it’s crucial to ensure the pH, ORP, EC and DO sensors are calibrated correctly before starting the monitoring process.

Tips for maintaining pH/EC/ORP/DO controllers

pH/EC/ORP/DO controllers require proper maintenance to operate correctly. One of the essential aspects of maintaining these controllers is cleaning the sensor probes. Deposits from wastewater can accumulate on the sensors and affect their accuracy. Additionally, calibrating the controllers periodically can help maintain their accuracy. These controllers are electronic devices, so it’s essential to ensure they are protected from electrical interference and power surges to avoid any damage.

6. Benefits of Water Effluent Monitoring for the Environment

Water effluent monitoring using pH/EC/ORP/DO controllers is beneficial for the environment in several ways.

Protecting water sources and aquatic life

Water effluent monitoring helps ensure that wastewater discharge from treatment plants meets regulatory standards and doesn’t harm the aquatic ecosystem. pH/EC/ORP/DO controllers monitor pH, EC, ORP and DO levels to prevent contamination of natural water sources.

Reducing pollution and its impact on the environment

Water effluent monitoring helps to keep the waterways clean by reducing pollution from wastewater discharge. By carefully monitoring the effluent, government regulatory agencies can hold the industries accountable and enforce regulations.

Wastewater eutrophication prevention refers to the measures taken to reduce or prevent the negative impacts of excessive nutrient loading in water bodies due to wastewater discharge.

Excessive nutrients from treated or untreated wastewater can cause the growth and proliferation of algae and other organisms, leading to a depletion of oxygen levels in water bodies, which results in fish kills and destruction of aquatic habitats. Failure to prevent such pollution could lead to huge costs in environmental damage and public health risks.

To prevent these damages, various technologies are utilized for effective treatment of waste before discharge into aquatic environments while water quality parameters are also monitored routinely by regulatory agencies.

Effective policy frameworks like proper effluent discharge standards are put in place with strict implementation for strict compliance by industries that generate wastewater before discharging them into surface waters.

Eutrophication effect on fish farming worldwide

7. Conclusion

The future of monitoring equipment is promising, with the increasing focus on reducing water pollution and improving water quality. The use of process control will continue to grow, and future developments will allow for more efficient and accurate monitoring, ultimately helping to protect our environment.

In conclusion, water effluent monitoring has become an essential practice for monitoring wastewater and surface water.

The benefits of using controllers are numerous, including real-time monitoring, accurate measurements and reduced environmental risk.

By implementing the proper installation and maintenance techniques, we can ensure the longevity and efficiency of equipment.

As technology continues to evolve, we can expect even more advanced systems to emerge, leading to even more comprehensive water effluent monitoring.

Have questions?

Contact a Hanna Technical Specialist at info@hannaservice.eu or using our contact form.

AUTHOR: Nives Vinceković Budor, dipl.kem.ing.

SOURCES: https://otpadnevode.hannainst.hr/