The term general or universal logistics includes the processes of production, processing, finishing, maintenance, packaging, signing (marking), stacking, sorting, weighing, measuring, loading (unloading), unloading, transhipment , tramping (transfer), storage, filling and emptying of containers and means of transport, transport (transport), fumigation, rodent control, disinsection, forwarding, agency, customs clearance insurance, sale, distribution, marketing, management, calculation, financing, controlling of goods.

Temperature

Plays a crucial role in most of this process of transport & logistics. The health of all clients and users is often reliant upon temperature in many ways as well. Maintaining proper temperature levels in storage areas is critical. Temperature-controlled transport is a complex topic, covering much more than merely getting goods from one place to another.

According to European Union, there are several regulations and recommendations for transport and logistics.

-

increasing the level of product and process safety,

-

protection of human health and life and environmental protection,

-

promoting the quality of products, processes and services

-

ensuring the purposeful use of labor, materials and energy, improving production efficiency,

-

removing technical barriers to international trade

Hygiene regulations by EU practice

- Establish and implement „good hygiene practices“

- Establish and implement a self-inspection system on the basis of HACCP

- Annual temperature recorder inspections as per EN 13486

- Documentary evidence

Each distributor and transporter is required to adhere to the following protocols:

-

Precooling of the vehicle used to transport the goods

-

Steps to ensure the circulation of air in the trailer (of particular importance on vehicles with double-decker beams, two-level loading and tall loads)

-

Checking of the required transport temperatures (logical and appropriate to the load)

-

Regular checking of the temperature indicators on the trailer

-

Selection of an appropriate parking space (avoid the midday sun in high summer)

-

Keep the doors of the trailer shut for as long as possible

-

Driver and the recipient should measure the temperature of the goods

-

Ensure confirmation of correct delivery

In every industry that involves food temperature of food and the premises where that food is produced, stored and transported, you should constantly control the temperature to minimize the risk of harmful levels of bacteria.

Products that are at high risk of developing harmful bacteria is meat products. Dried goods and vegetables and salad are also likely to contain bacteria if the food is on premises that have poor temperature control. Perishable food should always be controlled to prevent the growth of harmful bacteria.

Taking down the temperature on the paper, at least twice a day, could be exhausting and time consuming. There is a modern solution for your problems in Hanna Instruments. Log on with our loggers and keep logging.

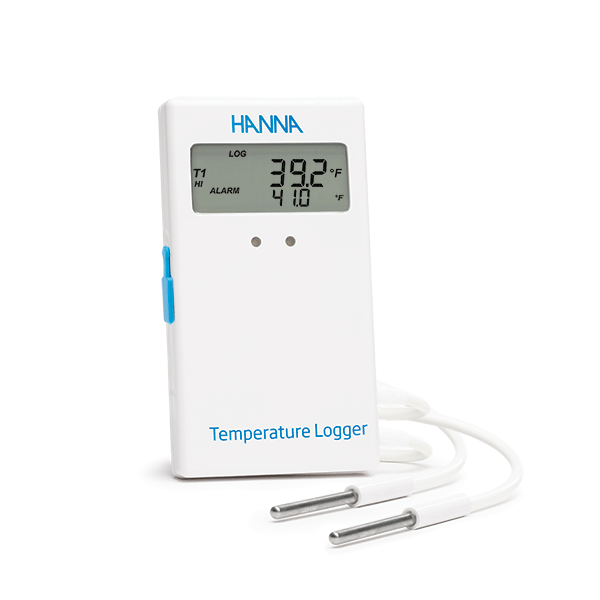

HI148 Temperature Datalogger

Quick to setup, simple to use, the HI148 is a datalogger that is ideal for monitoring and recording temperature in applications such as food processing, transportation, museums, and horticulture.

Choose between 4 models and store up to 16000 records!

- Thin and Rugged Design

- Multiple Sensor Options

- Programmable LCD Display

- PC Connectivity

- Customizable Program Settings

- Programmable high and low alarm limits with visual LED indicators

- Data Retrieval and Analysis

Hanna Instruments solution for HACCP color coding

Checktemp® 4 Folding Thermometer – HI151

The HI151 Checktemp® 4 is a folding thermistor thermometer that can measure temperature up to 300 °C (572 °F). These thermometers offer many advanced features including CAL-Check for an internal verification of the electronics and a motion sensor which eliminates the need of closing and reopening the probe when the meter enters a power saving mode. The Checktemp 4 is available in six different colors which can be assigned to different products to avoid cross contamination in the restaurant, kitchen or production facility.

- CAL Check to verify meter performance

- Waterproof to IP67 Standards

- Wake on Motion Sensor

- Ergonomic Design with Rubberized Grip

- Penetration Probe

- Instrument Quality Certificate for Traceability

Author: Tajana Mokrović, mag.nutr