The established electrochemical DO measurement is gradually being replaced by the optical measurement method.

Need assistance?

ISO 17289:2014 Water quality Determination of dissolved oxygen — Optical sensor method

ISO 17289:2014 specifies an optical method for the determination of dissolved oxygen in water using a sensor working on the basis of fluorescence quenching.

Measurement can be made either as a concentration of oxygen in milligrams per litre, percentage saturation (% dissolved oxygen), or both.

Depending on the instrument used, detection limits of 0,1 mg/l or 0,2 mg/l can be reached according to the manufacturer’s manual. Most instruments permit measurement of values higher than 100 %, i.e. supersaturation.

Fast. Simple. Reliable.

Advantages

Established electrochemical dissolved oxygen measurement methods require maintenance performed by the user on a regular basis.

Cleaning, calibration, membrane and electrolyte changes, polishing of the anode and the documentation of these activities were considered to be necessary and unavoidable.

With the innovative, optical measuring method, an alternative is available.

Compared to the electrochemical measuring method, there are considerable advantages for the user when using the optical method with regard to the quality of the measured values and the required maintenance effort.

The optical method for measuring dissolved oxygen eliminates the process-related disadvantages of traditional electrochemical measurement methods

No membrane - and electrolyte changes

Optical DO probes work without membrane and electrolyte.

Less frequent calibration

The optical measurement method attributes the measurement of the oxygen concentration to a drift-free measurement of time. Any wear or fading of the luminescent material on the sensor cap will affect the intensity, but not the lifetime of the red emitted radiation.

This is determined solely by the oxygen concentration of the sample. All optical components are adjusted before each measurement by the light pulse of the red reference LED, which exactly follows the beam path of the luminescent radiation.

Faulty calibrations by the user are excluded.

High measurement accuracy

The high-energy blue excitation light guarantees the consistently high measurement accuracy of the sensors.

No incident flow

Electrochemical measurement techniques evaluate the current flow or voltage caused due to the reduction of oxygen to hydroxide ions at the cathode. To compensate for this "oxygen consumption", a constant diffusion of oxygen molecules into the electrolyte is required.

The depletion of oxygen molecules immediately in front of the sensor can only be prevented from flowing sample against the sensor. No oxygen molecules were consumed in the optical measurement process.

Shorter response times

In the optical method, the oxygen molecules only have to be in contact with the luminophore. The response times of the optical measurement method are therefore in the range of seconds.

Higher sensitivity at low oxygen concentrations

The sensitivity of the measurement effect (change in the lifetime of the luminescence radiation / change in the oxygen concentration (Fv /FcO2 )) increases with decreasing oxygen concentration.

The measuring principle, therefore exhibits particularly good resolution in the lower measuring range.

Science behind it…

The principle of operation is based on the principle of fluorescence quenching and features an immobilized Pt‑based luminophore that is excited by the light of a blue LED and emits a red light. Dissolved oxygen quenches this excitation.

When there is no oxygen present, the lifetime of the signal is the greatest; as oxygen hits the sensing surface, the lifetime becomes shorter.

The intensity and lifetime are inversely proportional to the amount of oxygen present; as oxygen interacts with the luminophore it reduces the intensity and lifetime of the luminescence.

The lifetime of the luminescence is measured by a photodetector, and is used to calculate the dissolved oxygen concentration.

This is, in turn, reported by the meter as % saturation or mg/L of dissolved oxygen.

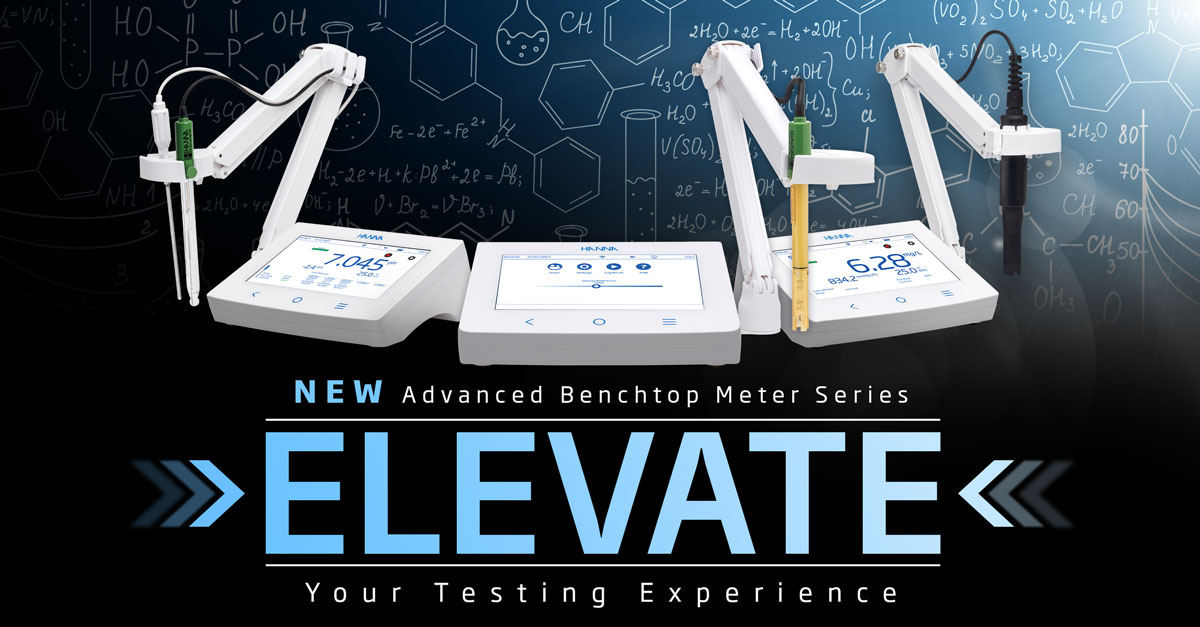

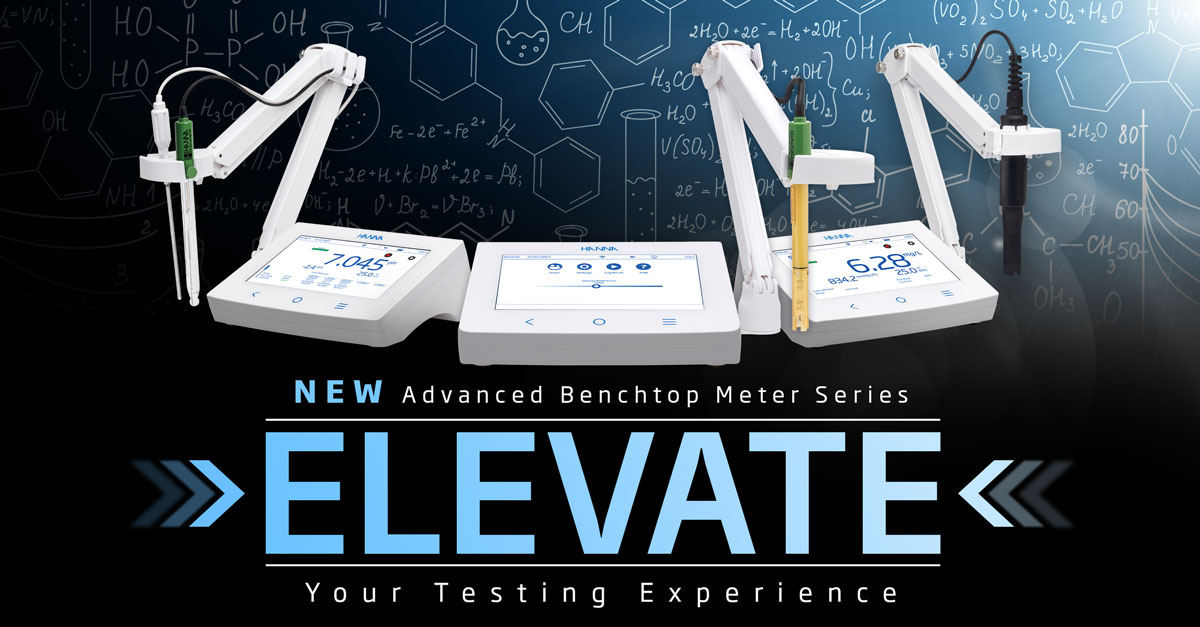

HI6421

Advanced Dissolved Oxygen Benchtop Meter with Optical DO Probe (opdo®)

HI6421 is an advanced benchtop meter with a capacitive display, comprised of a housing and an integrated dissolved oxygen (DO) measurement module.

Compact and easy to operate, HI6421 is delivered with HI7641133 optical dissolved oxygen (opdo®) probe.

Designed for fresh and saltwater measurements of dissolved oxygen, the system responds to a complex range of measurement and monitoring requirements, providing accuracy, reproducibility, and reliability.

HI7641133 optical DO probe (with HI764113‑1 Smart Cap) provides accurate DO measurements over long periods of time reducing the need for frequent calibration.

The Smart Cap, pre‑loaded with calibration coefficients, includes the immobilized O2 sensitive luminophore with rugged, insoluble black oxygen permeable protective layer.

Smart Cap

Additional features include:

built-in methods and calculations for the measurement of BOD (Biological Oxygen Demand)

OUR (Oxygen Uptake Rate)

SOUR (Specific Oxygen Update Rate)

Measurement & Calibration:

- Measure DO expressed as:

- %Sat

- mg/L

- ppm

- Application specific profiles allow quick and direct measurement without the need to update the sensor and system settings

- Active log during measurement

- Measurement stability indicator (using the Stability Criteria setting)

- Reading modes: direct and direct/autohold

- Temperature compensation can be Automatic (using integral temperature sensor within probe) or set manually

- Audible and/or alarm messages for measurements outside predefined limits

- Automatic or Manual assigned standards for calibration

- One or two points automatic calibration at 100.0 % (8.26 mg/L) and 0.0 % (0.00 mg/L)

- Single point manual calibration using a value entered by the user in % saturation or mg/L

- Non volatile memory for data storage and settings

HI7040L

Zero Oxygen Solution Set (500 mL)

HI7040L is a high quality, bicomponent zero oxygen solution made from reagent grade chemicals.

Hanna dissolved oxygen solutions have the lot number and expiration date clearly marked on the label and are air tight with a tamper-proof seal to ensure the quality of the solution.

- Prepared with reagent grade chemicals

- Hassle-free, easy to mix chemical component bottles

- Air-tight seal to ensure the quality of the solution

Logging

- Data log collection of at least 1000000 data points (with time and date stamp)

- Logging types: manual, automatic, autohold

- Sample ID for manual and autohold data

Connectivity features & services

- Transfer logged data to a USB thumb drive

- Log files include measurements and calibration data (as .CSV file)

- FTP and email for log export via Ethernet and Wi‑Fi connection

- Download logs using the benchtop’s embedded web server

- USB type A for USB drive, printer, and keyboard

- USB type C for USB drive and PC connection

User‑support feature

- Help section – brief overview of instrument’s main functions and features

Have questions?

Contact a Hanna Technical Specialist at info@hannaservice.eu or using our contact form.

Author:

Nives Vinceković Budor

dipl.kem.ing.

SOURCES:

https://www.iso.org/standard/59515.html