Is a type of brandy that has a protected name by law. It is a strong alcoholic beverage obtained by perennial maturation of wine distillate in oak barrels. Cognac is produced only from selected grape varieties that grow in a specific area of France. Production can last from several years to several decades. The stages of cognac production are: wine production, distillation, maturation, blending, addition of additives and finally bottling.

During distillation, special attention should be paid to the variation of the heating intensity of wine and brouillis. Better rectification will be more pronounced by slower distillation and will result in a dry-tasting Cognac. This is due to the lack of certain compounds left behind in the fraction. Faster heating results in Cognac getting a more intense flavor.

Hanna Instruments has a simple solution for monitoring the temperature during this process.

HI935001

Foodcare K-Type Thermocouple Thermometer with Interchangeable Probe

Designed with user functionality and performance in mind, the HI935001 is a waterproof K-Type thermocouple thermometer that measures temperature from -50.0 to 300°C (-58.0 to 572°F ). The included batteries provide up to 3500 hours of continuous use. CAL Check™ and the Battery Error Prevention System (BEPS) ensure the highest level of accuracy and confidence. The probe is replaceable and works with an assortment of specialized probes. This meter can be certified as traceable to NIST standards upon request.

- ±0.4°C/±0.7°F accuracy

- Enable automatic shut off after 8 minutes, 60 minutes, or disabled

- Perfect for use in industrial kitchens for wash-downs and cleaning of food processing equipment, as well as food packaging

- Not suitable for body temperature measurements.

Volatile compounds in Cognac

Cognac contains many compounds that contribute to the aroma of the final product. Hundreds of volatile compounds have been found in Cognac, including: acids, alcohols, esters, ethers, aldehydes, ketones and many others.

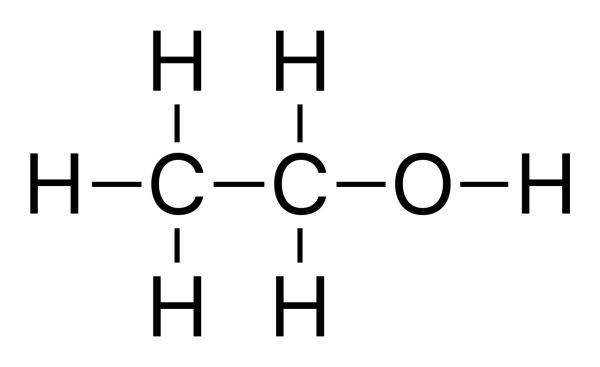

Ethanol

Is the most abundant alcohol in Cognac, and also a component immediately after water. Ethanol is produced in the process of fermentation by yeast cells. At the end of fermentation it is present in a concentration of about 10% vol./vol. By further distillation, the ethanol content increases to 70% vol./vol. In the continuation of the process, ie due to dilution and evaporation in the barrels, the ethanol content decreases to approximately 40% vol./vol. in the finished Cognac.

Observing volatile acids, acetic acid is the most abundant in Cognac. It is formed during fermentation and is formed by metabolic reactions of bacteria from acetaldehyde. Acetic acid is not desirable in higher concentrations due to the unpleasant acidic aroma, but therefore low concentrations are desirable because it will allow the formation of acetates of higher alcohols that are responsible for pleasant, floral and fruity aromas.

For measuring volatile components, Hanna Instruments has multi-purpose solutions tailored to each “Master Blender”.

HI801

Spectrophotometer Iris

IRIS portable spectrophotometer is unlike any of the products we have created in the past. It is different from our photometers as it allows for measurement in the spectrum of all wavelengths of visible light and not just pre–specified wavelengths. Spectrophotometers work by isolating light at specific wavelengths from white light. This compact meter incorporates a number of features that facilitate both fantastic performance and exceptional usability.

- Advanced split beam optical system

- Rechargeable li-ion battery

- User customizable methods

If you wanna learn more, contact us for more information!

Author: Tajana Mokrović, mag.nutr