HI510

Universal Process Controller

pH/EC/ORP/Temperature/DO

Water treatment can be made in many different applications and usually all process water should be treated no matter if they enter or exit the process.

Entering water is often treated and neutralized in order to stabilize the pH and avoid equipment corrosion.

Exit water are treated in order to avoid contamination and any adverse effect on natural aquifers. pH Neutralization of wastewater is a critical step in most industrial wastewater treatment processes. There are a multitude of regulatory requirements regarding wastewater discharge.

Water treatment can be made in many different applications and usually all process water should be treated no matter if they enter or exit the process.

Entering water is often treated and neutralized in order to stabilize the pH and avoid equipment corrosion.

Exit water are treated in order to avoid contamination and any adverse effect on natural aquifers. pH Neutralization of wastewater is a critical step in most industrial wastewater treatment processes. There are a multitude of regulatory requirements regarding wastewater discharge.

The aim of neutralization is to modify acidic wastewater to a neutral or target pH level before discharge. Any company that discharges into sewer systems, lakes, streams or other surface waters are required to neutralize this effluent before allowing it to be discharged or treated further in biological processes, such as anaerobic or activated sludge. In many instances, recording the pH of the discharge is also required.

Chemicals used to neutralize wastewater

Most commonly used chemicals include:

- sodium hydroxide (caustic soda) and

- calcium hydroxide (lime)

However, these compounds are reactive and can cause high pH levels if not controlled correctly..

ACIDIC

NEUTRAL

BASIC

pH Neutralization Systems

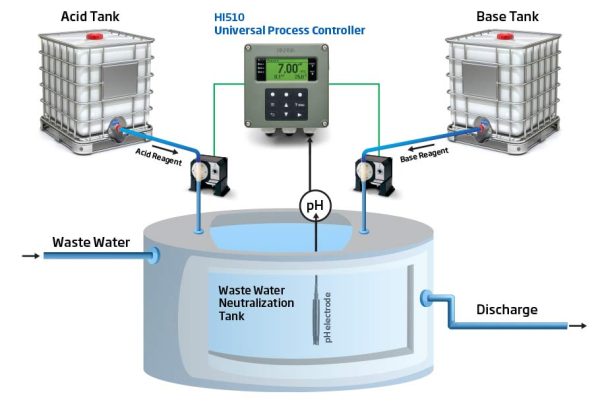

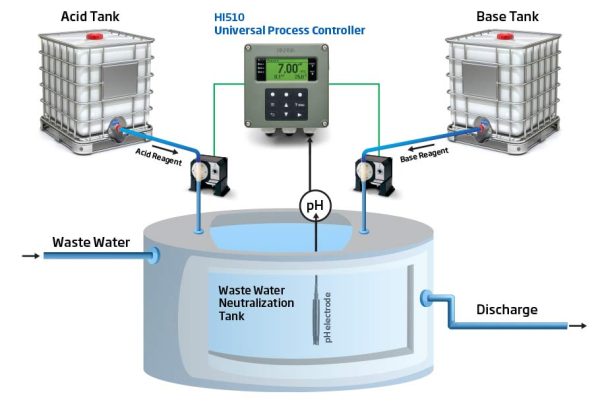

Many wastewater plants require a system that automates the monitoring and controlling of pH in the effluent by chemical addition.

In a typical system, effluent flows into a holding tank where a pH sensor measure the pH of waste. The controller has a targeted pH Set-point for the effluent and the waste should be tested to be in compliance with needed values. If the waste isn’t compliant with this target, pumps are used to inject alkaline or acidic solutions to balance the effluent to the correct targeted level. The solution should be continuously mixed in a mixing tank or with the agitators, to ensure good homogenization and allow pH sensor to take representative measurement, as well as ensuring good mixing between the effluent and added chemicals that may be added to balance the pH.

After the neutralization is completed, and the effluent has been balanced to an acceptable pH level, it can be discarded to waste.

At the point of effluent discharge, additional pH sensor can take an exit value reading and log the data.

Treatment can be done in simple way of adding a pH controller to the process monitoring and automatize addition of acid or base in order to obtain the Setpoint value of targeted pH.

HI510 is an advanced universal process controller that can be configured for many applications requiring monitoring and/or control of process parameters. It features a digital probe input that will automatically detect and update the controller with the parameter that it measures.

The HI510 offers wall, pipe and panel mounting options.

HI510 is designed to adapt to a user’s unique process control requirements. The controller has a large backlit dot matrix display for easy viewing and provides for a intuitive interface for setup options.

The controller utilizes multi-color LEDs for easy viewing of the instrument’s status including relay activation, in alarm mode, or in hold status. All programming operations are done through the low profile vulcanized rubber keypad or with an RS485 connection to a PC running the HI92500 Windows compatible software.

- Waterproof IP65 (NEMA 4X) enclosure

- Large backlit LCD

- Multi-color LED status indicators

- Audible alarm

- Tactile rubberized keypad

- Universal mounting

- Universal Hanna digital probe

The control mode can be configured to be:

- On/Off,

- Proportional or

- PID types.

The mode can be set high or low. High control mode is required if the process value is too high and needs to be decreased.

Low control mode is required if the process value is too low and needs to be increased.

Digital Inputs

- Two digital inputs are available for remotely triggering, cleaning and hold functions

Analog Outputs

- Available with up to four analog outputs and 5 relays used for control and for sending a signal to data loggers, PLC, SCADA and other remote monitoring systems

- 0-20 mA or 4-20 mA

- Scalable in selecting values for the range

- Can be used for control of pumps and valves

Digital Communications

The Hanna HI92500 PC application supports communication between the controller and a PC.

The following tasks may be

accomplished remotely:

accomplished remotely:

- Monitoring using the virtual LCD (limited to a single remote control in the entire network)

- Setup

- Loading the Setup configuration file to a controller

- RS485 Digital output for PC and other device connectivity

- Daisy-chain up to 32 devices to a remote monitoring system

pH/EC/DO/ORP/temp

Besides pH, Universal process

controller can be used for monitoring

of EC, D.O. and ORP

Industrial Smart Probes Compatible with the HI510 Universal Process Controller

pH and Temperature

- HI1006-18 and HI1016-18 series,

designed for low conductivity or low temperature process environments

ORP and Temperature

These smart industrial ORP probes are used for the measurement of the ratio of oxidized to reduced species in the process. Together with the Hanna Instruments HI510, they can monitor and control disinfection chemicals or follow and control a critical oxidation or reduction reaction.

- HI2004-18 and HI2014-18 platinum sensor series, designed to provide the best response over a wide range of applications

Conductivity

and Temperature

Recommended for clean, noncorrosive water applications, the HI7630-28 series can be calibrated using a standard with a value close to the measurement value.

The HI7630-48 series provides an exceptionally stable measurement over a

wide measure range and does not require frequent calibration.

Probes can be installed directly in-line, immersed in a tank, or flow cell.The

conductivity probes are suited for continuous measurement of conductivity

and associated parameters required in applications such as water treatment,

drinking water, feedwater condensate, or other clean water applications.

Galvanic

Dissolved Oxygen

The HI7640-18 series are galvanic-style oxygen probes

designed for use with the Hanna Instruments HI510 Universal Process Controller. The probe is suited for continuous measurement of oxygen dissolved in water. An integral temperature sensor measures water temperature and adjusts the probe signal over the specified temperature range.

The result is reliable dissolved oxygen (DO) concentration or percent saturated measurements.

Suitable for control applications in municipal and industrial wastewater treatment, the probe can be installed directly in-line, immersed in a tank, or in a flow cell installation.

Optical

Dissolved Oxygen

The HI7640-58 series are optical dissolved oxygen probes with

HI764113-1 DO Smart Caps for measurements of dissolved oxygen.

When paired with the controller, the system provides accurate DO measurements auto-compensated for barometric pressure, salinity (manually set), and temperature.

Suitable for control applications in municipal and industrial wastewater

treatment, where optimizing oxygen transfer is a key element, the

probe can be installed directly in-line, immersed in a tank, or in a flow

cell installation.

- Factory calibrated Smart Cap

- Low maintenance (no electrolyte refill or membrane replacement)

- Measurement reliability independent of flow rate

- Reduced response time

- Stable readings even when oxygen concentration is low

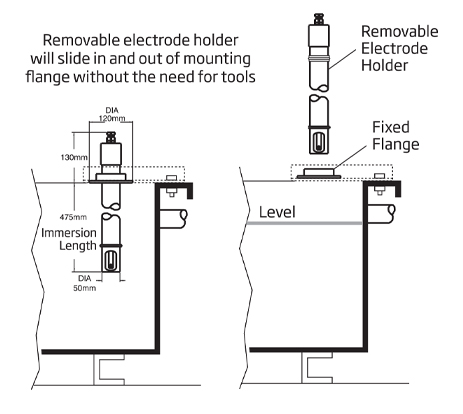

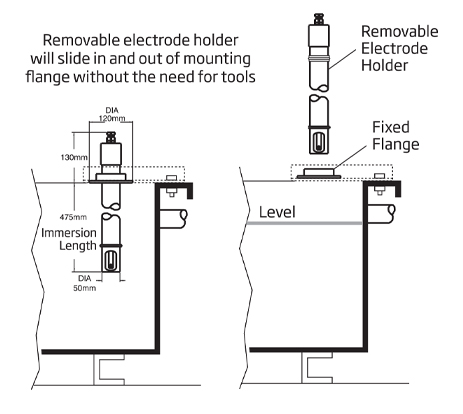

Probes can be installed directly in the tank with specifically designed electrode holders

The HI60501 is an electrode holder for immersion installation for tanks, vessels, baths and open channels. This electrode is made of rugged PVC, and can withstand most chemicals.

Once mounted to the tank, the electrode holder is a sturdy, protective housing that will extend the life of the electrodes. The electrode slides into the holder and is hand tightened into place. The cable from the electrode will lead up through the holder and out through the cap on top. The cable is also shielded inside the holder to prevent any damage to the insulation. The protective cap is removable to allow for quick and simple electrode maintenance and replacement.

Author:

Nives Vinceković Budor

mag.ing.chem.ing

Nives Vinceković Budor

mag.ing.chem.ing

With Great Product Come Great Results