If you are thinking about Pét-nat production you should refer to these parameters in the initial raw material. It is recommended to use a low alcohol (≤12% alcohol v/v), low pH (<3.50) wine if the bottle conditioning technique would be implemented. Enough residual sugar should be present (8-15 g/L) to generate 3-4 bar of pressure, maximum, and bottled with a yeast addition. Bottles have to be able to retain pressure and should be sealed with a crown cap. Since the pét-nats can create a fair amount of pressure in the bottle, winemakers should proceed with caution.

The pH should be lower than <3,50 and this pH will offer microbial protection to the wine through the production. Cellar hygiene, or proper sanitation techniques, will be essential for quality control purposes through production.

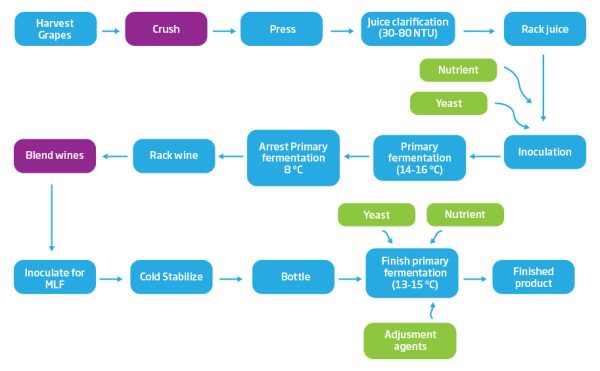

In the production process of pét-nats, some attention should be given to clarification of the juice, pre-fermentation. It is recommended that juice is clarified to 30 – 80 NTUs with use of centrifugation, flotation or assistance with settling enzymes and/or fining agents. In the juice-settling phase, a sulfur addition may help clarify the juice and minimize spoilage yeast and bacteria that could harm the quality of the wine.

Fermentation should proceed at 14-16°C. When the amount of alcohol will be at about +/- 3% v/v from the target alcohol, wine have to be chilled down to 8°C to hinder the fermentation. After cooling, wine needs to be racked to remove most of the lees. It can be removed by centrifugation or filtration. Furhermore, after this procees, wine has to be restart with a fresh culture and hydration nutrient.

Then, the base wine is re-inoculated in the bottle and the fermentation will proceed in the bottles. The temperature needs to be control, optimally set at 13-15°C. For retention of residual sugar, chill the room to 0-2°C to arrest fermentation in the bottle.

of Pétillant Naturel Sparkling Wines (Méthode Ancestrale)

HI96813

for Measurement of Sugar in Wine

- Sample size as small as 2 metric drops (100 μl)

- Sealed stainless steel well with high-grade optical prism made of flint glass

- Fast 1.5 second response time for temperature compensated readings

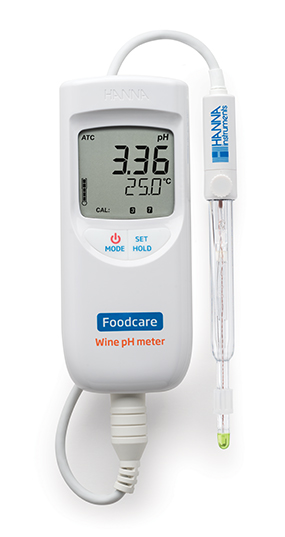

HI98169

for wine

HI98169 is a robust, waterproof, portable pH meter for wine that measures the pH and temperature of must in winemaking. This meter comes with a specialized pH probe that has open connection properties with clogging prevention system (CPS).

HI99111

- ±0.02 pH accuracy

- Comes with all the necessary solutions and batteries- everything you need to get started measuring right away.

- Specialized for the pH measurement of juice, must, and wine during the wine making process.

HI83749

Turbidity Meter

and Bentonite Monitoring

- Log and transfer up to 200 measurements.

- GLP (Good Laboratory Practice) feature for traceability of the calibration conditions.

- Great for small & medium wineries and advanced hobbyists.

you should measure it with

HI83746-02

for Reducing

Sugars in Wine

- Built-in Timer

- Automatic Shut Off

- Ready-made Reagents

This is simple solution for that from Hanna Instruments.

HI98539

Checktemp Dip

Tajana Mokrović

mag.nutr.