Ultrapure water (UPW) is an indispensable element in numerous processes, particularly those commonly used within the pharmaceutical sector.

It serves as a critical ingredient in the manufacturing process of various pharmaceutical formulations, such are:

- injections

- infusions

- oral medications

Ultrapure water is classified based on its exclusive composition of H2O, with equal concentrations of H+ and OH– ions.

This rigorous purification process results in ultrapure water having a conductivity of approximately 0.055 µS/cm at 250C.

Measuring water conductivity is crucial for researchers and scientists as it enables them to obtain precise information about the composition of the water they are working with, ensuring accurate results.

Contaminants present in water, such as bacteria, viruses, particulates and trace impurities, can adversely affect the efficacy, stability and safety of pharmaceutical products.

Importance of Ultra-Pure Water:

Manufacturing Processes

Ultrapure water serves as a key ingredient in pharmaceutical manufacturing. It is used in formulation, blending, washing and dissolving various compounds.

The high purity of the water ensures that the active pharmaceutical ingredients (APIs) and other components aren’t contaminated, thereby maintaining the efficacy and safety of the final products.

Quality Control

Accurate testing and analysis are crucial in the pharmaceutical industry to meet regulatory standards. Ultrapure water is utilized extensively in laboratory testing, such as sample dilution, calibration and equipment cleaning.

Contaminants in water can affect the accuracy of analytical results and equipment cleaning, making ultrapure water essential for reliable quality control.

Cleaning and Sterilization

Maintaining a clean and sterile environment is very important in pharmaceutical facilities. Ultrapure water is used for equipment and facility cleaning, as well as for sterilization purposes. It helps to prevent the introduction of microorganisms and other impurities that could compromise the quality of pharmaceutical products.

Ultrapure water, used extensively in pharmaceutical applications, must meet specific critical parameters to meet regulatory standards.

Here are some of the essential parameters to consider for ultrapure water in Pharmaceutical Water Systems:

Conductivity

Low conductivity is a crucial parameter for ultrapure water. It indicates the absence of dissolved ions and impurities that could interfere with pharmaceutical processes and impact product quality.

The conductivity of ultrapure water should ideally be below a certain specified limit, usually measured in microsiemens per centimeter (µS/cm).

Total Organic Carbon (TOC)

TOC is a measure of the organic carbon content in water. It is an essential parameter for ultrapure water quality because organic compounds can adversely affect the purity and stability of pharmaceutical products.

Strict limits are imposed on TOC levels, typically in parts per billion (ppb) or parts per trillion (ppt), depending on the application.

Microbial Count

Controlling microbial contamination is critical in pharmaceutical water systems. The presence of bacteria, fungi and other microorganisms can compromise product safety and stability.

Ultralow microbial counts are required, often specified as colony-forming units (CFU) per milliliter (CFU/mL), with strict limits set by regulatory guidelines.

Endotoxin Levels

Endotoxins are toxic substances released by the cell walls of certain bacteria. Even at low concentrations, they can cause severe adverse reactions in patients.

Ultrapure water used in pharmaceutical applications must have extremely low endotoxin levels, typically measured in endotoxin units per milliliter (EU/mL) or endotoxin units per liter (EU/L).

Particulate Matter

The presence of particulate matter in ultrapure water can lead to contamination and affect product quality. Particles can originate from various sources, including the water supply, distribution systems or equipment.

Strict limits are defined for the size and number of particles allowed in pharmaceutical water, usually measured in micrometers (µm) or particles per milliliter (particles/mL).

pH

The pH level of ultrapure water should be within a specific range to ensure compatibility with pharmaceutical processes and products.

The pH affects the stability and solubility of certain active ingredients and deviations from the required pH range can impact product efficacy and safety.

It is essential to continuously monitor and validate these critical parameters in ultrapure water systems.

Regular sampling, testing and validation procedures should be established to ensure ongoing compliance with regulatory requirements and industry standards.

For monitoring the main quality parameters of Ultrapure Water, HANNA Instruments has great solution!

HI98197

Ultra Pure Water EC/Resistivity Meter

The HI98197 is supplied complete with all accessories necessary to perform high purity water measurements packaged into a durable carrying case.

The accessories include a stainless steel flow cell and a threaded four ring conductivity probe that allows for high resolution 0.001 μS/cm for conductivity and 0.1 MΩ * cm for resistivity readings.

- Stainless steel flow cell

- Four ring conductivity/resistivity probe

- 0.001 μS/cm resolution

HI6000 Series Benchtop

HI6221

Advanced pH/ORP Benchtop Meter

HI6221 is a streamlined benchtop meter with a large touchscreen display, comprised of a housing and an integrated pH/ORP measurement module.

Compact and easy to operate, the benchtop meter is delivered with Hanna Instruments HI1131B double junction combination pH electrode, together with HI7662-TW temperature probe.

This system responds to a complex range of measurement and monitoring requirements, providing accuracy, reproducibility and reliability.

HI6321

Advanced Conductivity Benchtop Meter

HI6321 is a streamlined Conductivity / Resistivity / TDS / Salinity / Temperature benchtop meter with a large touch screen display, comprised of a housing and an integrated conductivity measurement module.

HI2202 edge®

Smart pH Electrode and Meter

Free yourself from wires when performing pH measurements. Hanna Instruments is proud to introduce edge® blu, a pH meter that uses pH electrodes with Bluetooth ® Smart technology (Bluetooth 4.0).

These pH electrodes connect wirelessly to edge blu or a compatible Apple or Android® device running the Hanna Lab App.

- Edge® blu uses HALO™ Bluetooth pH electrodes with a built-in temperature sensor to send measurement data wirelessly to the meter or a compatible Apple or Android device running the Hanna Lab App.

- Edge® blu features advanced pH electrode diagnostics to ensure worry free measurements. Diagnostics include Hanna’s exclusive CAL Check feature that alerts users to potential problems during calibration.

- Edge® blu features a capacitive touch keypad that gives a distinctive, modern look. The keypad is sensitive enough to be used with laboratory gloves and has a fast response.

Bluetooth Digital pH Electrodes![]()

edge®blu uses HALO® Bluetooth digital pH electrodes. Once a probe is connected, all sensor information including sensor operating specifications and calibration information is transferred.

pH electrodes are easy to exchange when you want to change from measuring with one type to another without the need for recalibration.

Water Purity Testers

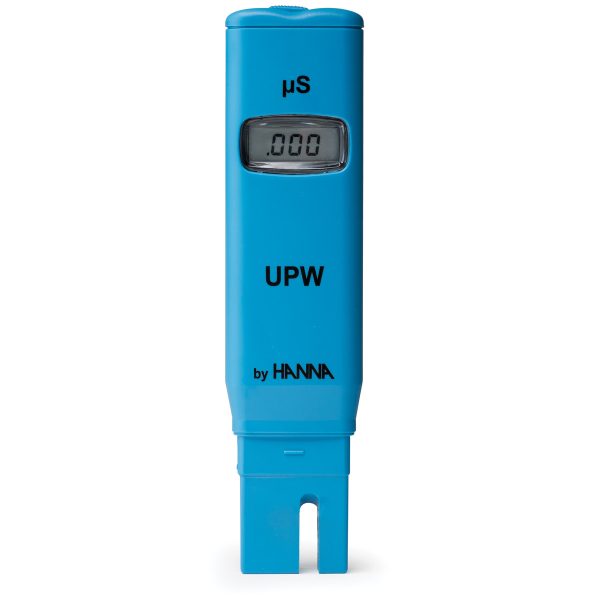

HI98309

Factory calibrated

The HI98309 UPW is the first pure water tester/conductivity meter to measure in 1/1000ths of micro-Siemens and provides on-the-spot and fast checks for minute traces of contamination in your water, assuring high quality of finished products in processes.

A rugged, pocket-sized tester that features graphite electrodes to reduce polarization effects. The HI98309 comes already calibrated, done with freshly prepared low-conductivity solutions in factory due to the high instability of calibration solutions in the UPW range (below 2 µS/cm).

- Exposed temperature sensor for fast response

- Accurate readings of ultra low range 0.000 to 1.999 µS/cm

- Factory calibrated

HI98308

Single point manual calibration

The HI98308 Pure Water tester is a rugged and reliable pocket-sized tester that offers quick and accurate readings.

The HI98308 Pure Water tester features graphite electrodes to reduce polarization effects and an exposed temperature probe for fast response when compensating for temperature changes. Manual calibration is performed to a single point.

- Exposed temperature sensor

- Very low range EC (0.0 to 99.9 μS/cm)

- Single point manual calibration

With Hanna, everything is certified.

At the time of purchase, you will also receive two quality certificates: one regarding the instrument and one regarding the probe. These documents certify that the products meet and exceed all quality requirements.

Over time and use, the characteristics and performance of the instrument tend to change. Therefore, a periodic metrological check and calibration are necessary to ensure that the instrument continues to work according to quality standards and therefore always provides reliable values.

Contact our sales team to request a periodic check and calibration of the instruments.

SOURCES:

1. Kanak Lata Verma, Rohan Verma (June 2015): Importance of Ultra Pure Water in Analytical Methods For Determination of Drug of Abuse by Mass Spectrometry

2. Suleman S, et.al: Quality-by-Design Principles Applied to the Establishment of a Pharmaceutical Quality Control Laboratory in a Resource-Limited Setting (2022) doi:10.1155/2022/2062406

Have questions?

Contact a Hanna Technical Specialist at [email protected] or using our contact form.