We all know that getting accurate measurements is crucial in wine production. The last thing you need while working in your wine lab is to realize halfway through that you’re missing something from your supply or that a piece of equipment isn’t working properly.

The Hanna team has put together this guide to help you set up your wine lab for testing and keep up with regular maintenance along the way. By following these eight steps, you can be sure that your wine lab is always ready to handle all your testing needs including pH, SO2, ORP, TA, and refractometry.

- Restock Calibration Buffers

- Stock the Right Cleaning Solution

- Use Electrode Storage Solution

- Check the Electrode Fill Levels

- Check That Your Electrodes are Functioning Correctly

- Stock Back-up Electrodes

- Consider a Mini Titrator

- Upgrade to a Digital Refractometer

1. Restock Calibration Buffers

pH electrodes should be calibrated before use. Ideally, daily calibrations should be performed to keep your measurements accurate. Over time an opened bottle of the buffer will degrade, and the pH value on the bottle will not be the actual pH value of the solution. For this reason, you should replace any buffers that have been opened for more than six months, regardless of the expiration date on the package.

Print out our pH Best Practices Guide to hang in your lab as a reminder of this and other important tips!

The calibration buffers that are most used in wine production are the pH 7.01 buffer (500 ml) – HI7007L, the pH 4.01 buffer (500 ml) – HI7004L, and the pH 3.00 buffer (500 ml) – HI5003.

2. Stock the Right Cleaning Solution

Electrodes need to be clean in order to function properly. With pH probes, stains or coatings on the sensitive glass surface will cause a change in the voltage generated by the pH electrode in a solution. You also need to watch for clogging of the junction. Coatings on the glass or clogging of the junction will result in slow, erratic readings. Hanna recommends using the HI1048 electrode designed specifically for wine for best performance.

Hanna Tip: Use specially formulated cleaning solutions rather than general ones. For wine applications we recommend using Cleaning Solution for Wine Deposits (500mL) – HI70635L or Cleaning Solution for Wine Stains (500 mL) – HI70636L.

3. Use Electrode Storage Solution

Storage solutions (like Hanna’s Electrode Storage Solution (500 mL) – HI70300L) are designed to keep the pH bulb hydrated and maintain a flowing junction. After cleaning an electrode it should be hydrated in storage solution for least 3-4 hours, and an electrode should be stored in a storage solution at all times when not in use.

A dry junction slows down the flow of the electrolyte solution inside the probe. This impacts the junction potential as well as the stability and response of the electrode. Properly stored electrodes will exhibit higher accuracy and have a longer lifespan than ones that aren’t stored correctly.

Hanna Tip: Do you have a properly stored electrode that still isn’t performing like it should? Download our pH Electrode Troubleshooting Guide for more tips.

4. Check the Electrode Fill Levels

Refillable pH or ORP electrodes need to be topped off with electrolyte at a certain point. The fill solution should always be full in order to provide an adequate amount of pressure. This pressure allows for the flow of electrolyte through thejunction and into the sample. The ions in the electrolyte complete the electrical measuring circuit between the meter, electrode, and the wine sample being tested.

Hanna Tip: Remove the fill cap while testing to ensure electrolyte flow. Replace and tighten the fill cap to preserve electrolyte during storage.

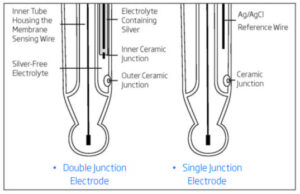

Single-junction and double-junction electrodes have different fill solutions

Don’t know what kind of junction your electrode has? The diagram below will help you identify it. Use our HI7082 solution if you have a double-junction electrode or the HI7071 solution for a single-junction.

5. Check That Your Electrodes are Functioning Correctly

pH Electrodes

Electrodes have a limited lifespan. A reading that takes too long to stabilize (more than 30 seconds) may be a sign that your electrode is failing.

To check the overall condition of a pH electrode you need to check two values: the offset (mV value in pH 7.01) and the slope (mV difference between pH 7.01 and pH 4.01). The offset and slope of a pH electrode should always be checked with fresh buffers. If your meter has a Good Laboratory Practice (GLP) option then it will provide the data for you after calibration.

If your meter does not have a GLP option, then any meter with a mV mode can be used to check the pH electrode.

Here are the instructions for checking slope and offset without GLP mode:

Offset

For a pH electrode placed in pH 7.01 buffer, the theoretical mV should be 0. However, due to variations in the glass, aging, and conditioning, the offset voltage will usually stray, so an acceptable offset voltage is +/- 30 mV. Most meters will allow calibration at values as high as +/- 60 mV for pH 7.01 buffer, but at this point the accuracy of your measurements will decrease.

Slope

The ideal slope for a pH electrode is 100% or 59.16 mV change per pH unit @ 25 ºC. For pH 4, this represents a 177.48 mV difference, since pH 4 buffer is three units away from pH 7 (59.16 mV x 3). The absolute minimum slope for an operable electrode is 85% or 150 mV (177.48 x 0.85).

If the offset and slope values are outside the acceptable ranges, try cleaning and hydrating the probe, then retesting. For refillable probes, you can take the additional step of changing the reference fill solution. If the values are still outside the range, your probe likely needs to be replaced.

ORP Electrodes

SO2 potentiometric Ripper titrations use an ORP electrode for determining the endpoint. It is important to periodically check the ORP electrode using an ORP test solution.

To check an ORP electrode, the probe is placed in an ORP test solution of a known value. Let’s use the HI7021L 240 mV @ 25°C ORP Test Solution (500 mL) as an example. A properly functioning electrode will read 240 mV +/- 50 mV. Readings outside this range indicate that the platinum tip and/or band need to be polished, or the electrolyte fill solution needs to be changed. If the ORP electrode cannot be brought within range, then it should be replaced.

Hanna Tip: Very fine sand paper, like 2000 grit, can be used to polish a tarnished ORP tip or band. The ORP sensing portion of the electrode should be shiny.

6. Stock Back-up Electrodes

Due to the limited lifespan of electrodes, we recommend that you have a back-up electrode in case yours fails.

We highly recommend using electrodes specifically designed for winemaking. Factors like body type, junction material, type of junction, fill solution, and the type of glass are all part of the design process. The right mix of materials and technologies significantly improves accuracy, ease-of-use, and the working life of the electrode.

Types and Benefits of Wine-Specific Electrodes

The HI1048 electrode series is designed with special features specifically for use by winemakers.

CPS Sleeve Junction

Hanna’s Clogging Prevention System (CPS) is an innovation in electrode technology. Conventional pH electrodes use ceramic junctions that clog quickly when used in the wine must. When the junction gets clogged, the electrode won’t function. CPS technology uses porous ground glass coupled with a PTFE (a material similar to Teflon™) sleeve to prevent clogging; the ground glass allows proper flow of the electrolyte, while the PTFE repels dirt. As a result, pH electrodes with CPS will require less maintenance and function longer than a conventional electrode would in wine production.

Double Junction Reference

A double junction electrode, such as the ones in the HI1048 wine series, has an internal compartment surrounding the reference wire. Silver ions are present in the electrolyte of the internal compartment, which houses the reference wire; the electrolyte outside this compartment is silver free. The double junction design means that virtually no silver from the electrode enters the sample. This design allows measurement in applications where silver ions in the sample are undesirable or silver precipitates on the junction are likely to form.

Electrode Connectors

The HI1048 electrode series comes available with a variety of connectors so they can be used with a wide range of meters and instruments. The two most popular connections are the BNC and 3.5mm connectors.

BNC – such as the pH Electrode with CPS and BNC Connector – HI1048B – are universal and can be used with any meter that has a BNC connector, like the Mini-Titrator for Measuring Titratable Acidity in Wine – HI84502.

A 3.5mm pin connection, such as the one on the Digital Glass Body pH Electrode with CPS – HI10480 for edge, is a digital pH electrode which contains a built-in microchip that stores information such as your sensor type, the serial number, and calibration information including the date, time, offset, slope, probe condition, and buffers used. The HI10480 has a built-in sensor for temperature compensated measurements.

This type of connection can only be used with our line of edge meters, which includes the edge Wine pH Meter Kit – 2020W, the edge Dedicated pH/ORP – HI2002, the edge Multiparameter pH – HI2020, the edge Multiparameter EC/TDS/Salinity – HI2030, and the edge Multiparameter DO – HI2040.

The wine-specific pH Electrode with CPS – HI10480 comes standard with the HI2020W Wine pH Meter Kit.

HALO Wireless Electrode

The HALO Bluetooth pH Electrode for Wine – HI10482 offers all the wine-specific features of the HI1048 wired electrode but saves you the cost of a meter. Once the free Hanna Lab app is downloaded onto your smart phone or tablet, your device becomes your meter!

Features of the Hanna Lab App include easy calibration, pH measurement, data logging, graphing, and data sharing. The HALO offers a great addition to your pH testing analysis tool kit both as a back-up and as an additional meter for high volume analysis periods.