Limited time deal

⭐ Use Code: DEAL15 ⭐

Get 15% OFF our popular Portable Turbidity Meter (HI98703)!

Deal Ends 4/30 - BUY MINE NOW

Surpass standards

Equip your lab with our versatile Benchtop Meters. Test various parameters, meet industry requirements, and ensure quality.

SHOW ME BENCHTOPS

Stop guessing

Say goodbye to water test strips. Get instant digital results in the palm of your hand with our convenient Checkers.®

PICK MY CHECKER

Popular Products

Over 3,000 precision instruments

With so many instruments to choose from; let us help you narrow it down with a few of our most popular categories.

Testers

Testers

Pocket-sized testers for pH, ORP, and EC, to take your testing where you need it.

Learn More

Portable Meters

Portable Meters

Test from wherever you are! Whether you are out in the field or in the lab, we have a portable meter for your application.

Learn More Benchtop Meters

Benchtop Meters

Simple to use and highly accurate! From benchtop meters and photometers to laboratory research grade meters, we have a variety to choose from.

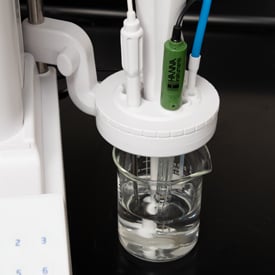

Learn More Titrators

Titrators

From manual to full-fledged automation, we can help you with your titration needs. Save time and have higher precision results with our line of automatic titrators.

Learn More Electrodes

Electrodes

If there’s an application, we have an electrode for it. Specialized electrodes give an ease to testing with faster response times and accurate measurements.

Learn More Solutions and Reagents

Solutions and Reagents

Buffers, standards, reagents and more to conduct your measurement procedures from calibration to results.

Learn More